Projects

- Ryegate Culvert Design-Build Replacement Project

- Franklin County State Airport Expansion – 2024

- New Haven – Ferrisburg Trenchless Culvert Project

- Pittsford Rail Bridge Rehab & Strengthening

- Renewable Energy Project – Vermont National Guard 2.2MW Solar Project

- AllSun Solar Tracker Installations

- East Alburgh Bridge Swing Span Automation

- Whipline Gas Bore

- Gentes Road Bridge Rehabilitation

- Hartford Bridge Street Bridge Replacement

- CCTA Downtown Transit Center

- Renewable Energy Project – Rock of Ages 100kW Wind Turbine

- Lime Kiln Substation Retaining Wall

- North Hero-Grand Isle Draw Bridge Emergency Superstructure Repairs

- City of Burlington Municipal Paving Contract

- Interstate 91 Rutfill Project

- Pinkham Notch Conduit System

- Grade Crossing at Rte 142 Vernon

- Bellows Falls Tunnel Clearance Improvements

- Burlington Tunnel Emergency Repairs

- VELCO 115kV Underground Electric Transmission Line

- VELCO & GMP Lime Kiln Substations

- VTrans Intelligent Information System (ITS)

- Vermont State Archive Fire Water Storage System

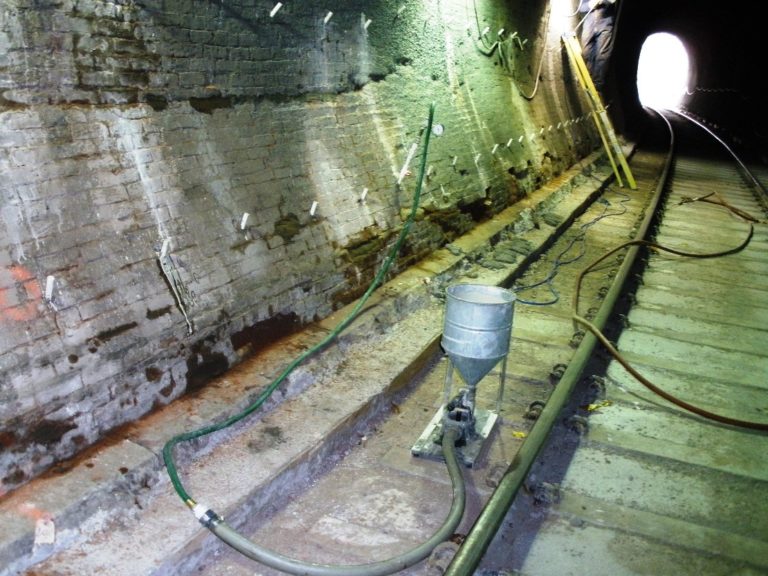

Burlington Tunnel Emergency Repairs

ECI’s Client: New England Central Railroad

Completion Date: December 2008

Subcontractors: Boscardin Consulting Services

ECI was engaged by the NECR to perform emergency stabilization of the Burlington Tunnel (located under North Avenue in Burlington, VT). A sudden loss of structural integrity of the tunnel floor caused significant ground movements and longitudinal cracking at the spring-line of the 150-year-old brick lined tunnel. The railroad immediately stabilized the tunnel by flooding the unstable areas concrete. ECI was called in to design/build a permanent repair. The design consisted of a concrete bearing curb on each side of the tunnel with a reinforced concrete track structure (steel cross ties and rebar encased in concrete) to serve as a cross strut to resist the lateral earth pressures. Our scope of work included:

Scope of Work:

- Evaluation of tunnel: cored through brick lining to evaluate crack depth and tunnel lining thickness, installed survey monitoring points and crack monitors; evaluated lateral earth pressures; designed permanent bracing

- Removal of the temporary concrete fill (which was higher than the proposed finish floor elevation) in segments and replacing with new concrete segments.

- Installation of the reinforced concrete curbs to act as a bearing for lateral forces transferred through the track structure.

- Installation and alignment of the steel cross-ties and rail.

- Grouting of cracks with a neat cement grout under low pressures.

The project is also described in a technical paper published and presented at the 2011 Rapid Excavation & Tunneling Conference in San Francisco.